Performance

The Dryclone® system’s performance, value, and positive environmental impact make the only commercial air drying solution of its kind. Its capabilities, coupled with high-volume throughput capacity, result in lower operating costs and higher processing efficiency.

HOW IT WORKS:

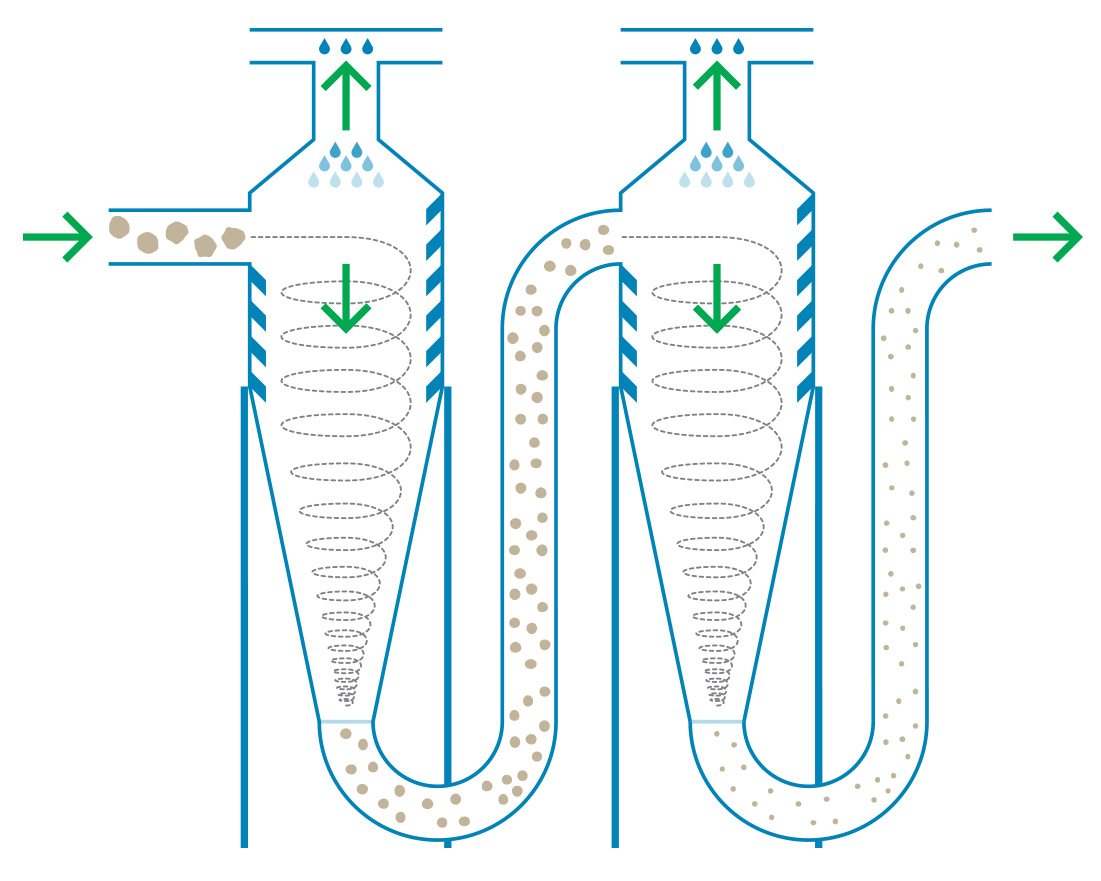

The raw material is fed into an airstream that reaches speeds of up to 400 mph (640 km/h). As the material is suspended and accelerated, it travels through a series of uniquely designed Dryclones. Within each Dryclone, its cellular structure is broken down and the moisture is separated from the raw material. Once separated, the water is embedded into the airstream and released through the top of each Dryclone and ultimately passed through a filtration system.

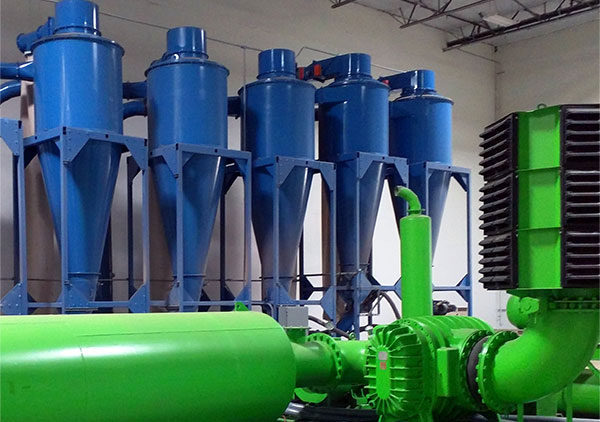

The Dryclone system is fully scalable and customizable. For projects requiring larger volumes, the Dryclone system is easily scaled and configured to accommodate an unlimited amount of raw material.

Although the standard Dryclone TL configuration is capable of processing up to 15 tons (13.5 metric tons) per hour, the Dryclone can also be configured for applications requiring less throughput per hour. The Dryclone can be configured to accommodate extra high moisture applications as well.

The Dryclone system can reduce moisture content to as low as 15% while reducing particle size, at a rate of up to 350 tons (315 metric tons) per day for each Dryclone TL system.

- Wet material is fed into an air stream and accelerated to high velocities before entering the first of several Dryclones.

- The combination of air velocity and impact in the Dryclones act on the feedstock to dry it and reduce its size.

- The number of Dryclones will vary depending upon initial moisture, degree of drying, throughput, and quality of the feedstock.